-

-

Your ESC will need to utilize RailCore's Enclosure system to connect to the battery, this means you'll need to build the compatible printed circuit board.

-

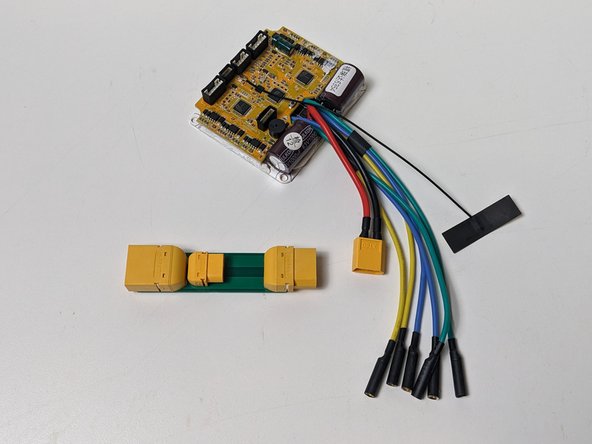

Gather all PCB Components and remove from the bag

-

Locate the small, metal pins located on the XT Connectors.

-

Snap off these metal pins by squeezing with pliers and bending them (they will snap)

-

-

-

Now that the connectors no longer have pins, it's now time to solder them to the PCB.

-

Gather your smaller XT60 Connector and align it with the holes in the middle of the PCB, with the port facing the middle. (Shown in photo)

-

The most important part of this step is that the connector lay flush with the PCB. There shouldn't be any variation in space between the connector and the PCB.

-

Use caution and care when using or operating around a Soldering Iron, as it can easily burn or cause harm.

-

Solder the XT60 to the underside of the PCB to attach it permanently.

-

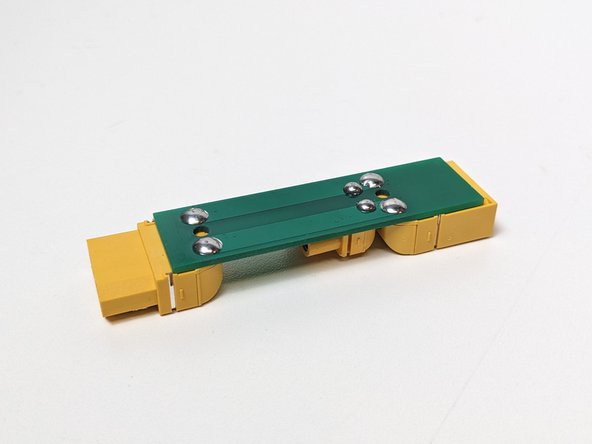

Solder points should have a round, bubble holding down the connectors. Any excess solder will prevent the PCB from sitting flush within the rail.

-

-

-

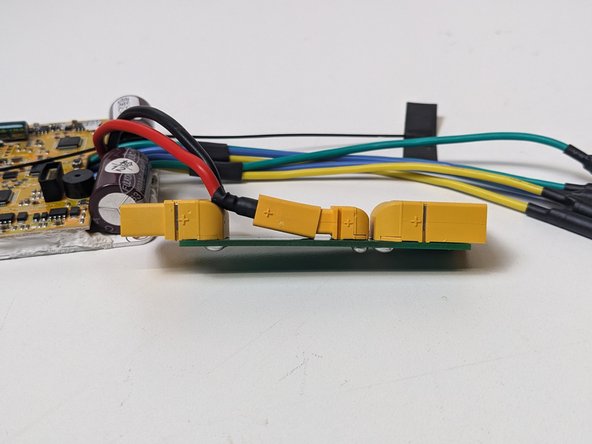

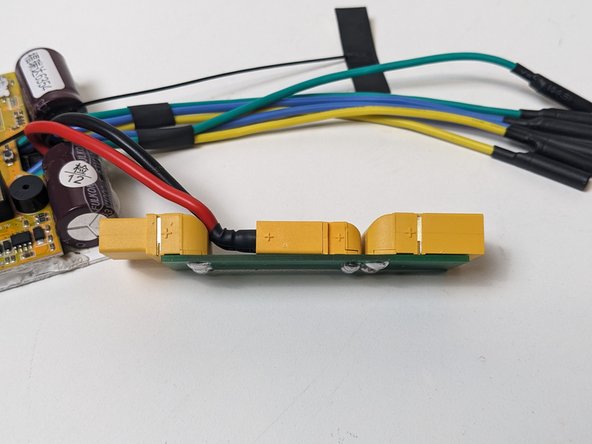

Now that you have your main ESC Port soldered onto the PCB, It's time to solder the battery connectors.

-

Align your plugs to be flush and parallel with the PCB. With the male connector on the shorter end and the female closest to your XT60 connector.

-

Solder the XT90 to the PCB, ensuring that the ports are stable and aligned properly.

-

Set your PCB aside as we continue to assemble your ESC.

-

-

-

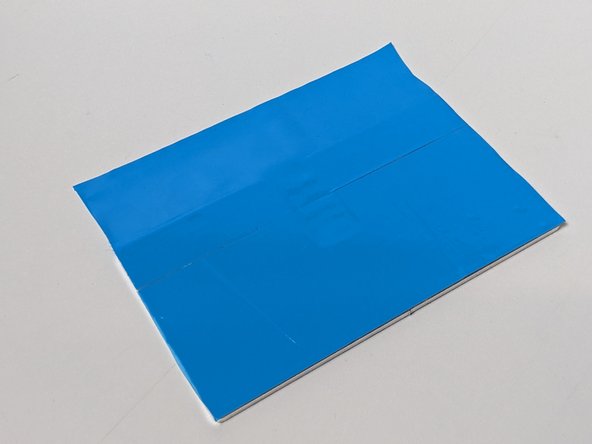

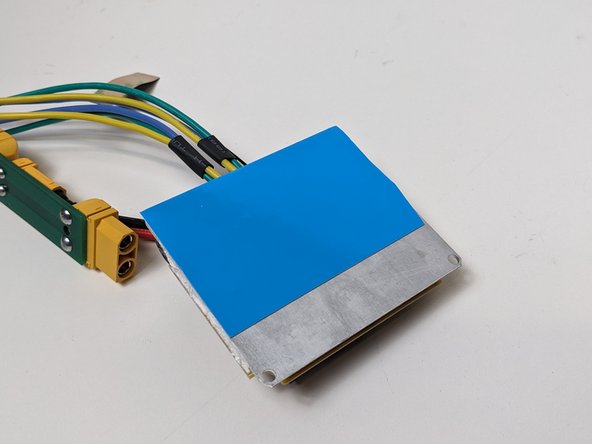

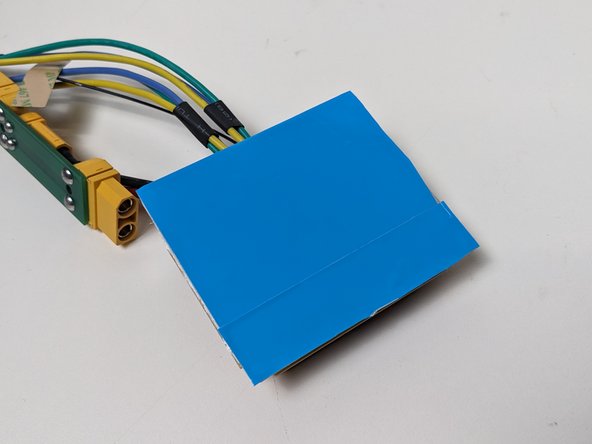

Grab your ESC Enclosure (Top & Bottom), Metal Heatsink, and Thermal Tape.

-

A heatsink is a device or substance for absorbing excessive or unwanted heat. In this case, (no pun intended) we're using these metal plates to absorb the heat of. the ESC.

-

Assure the heatsink is clean and dry. Place a strip of thermal tape over the entirety of one side of the heatsink.

-

Continued in next step

-

-

-

Trim the excess thermal tape and place aside (you can use the excess later if you're careful)

-

No need to trim on the Heatsink's cut-out. A regular rectangle shape is perfect.

-

Peel off the thermal tape's backing and install the heatsink into the TOP of the ESC enclosure by pressing firmly on the heatsinks 4 corners.

-

Make sure you're installing the heatsink on the correct side of the case and it is centered, as to not have a gap between the sink and the casing.

-

-

-

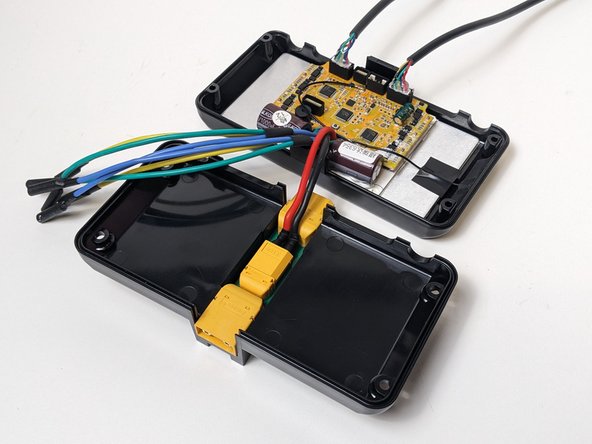

Gather an ESC and your finished PCB. It's now time to connect them.

-

Align the ESC's XT60 Connector with the PCB's. You'll notice that it does not appear to have enough room to connect these two ports...

-

While pushing the connectors together, you can push down to bend the ESC cables to fit into the space between the XT90's.

-

Do not push too hard! This connection while taking some force, should not come close to breaking either the PCB, ESC or connectors.

-

-

-

Add thermal tape to cover the entire backside of the ESC. (Here's where you can use that excess material!)

-

Trim the borders for minimal excess.

-

Align the ESC with the Heatsink. Your cables should be sprouting from the enclosure side with NO CABLE PORTS. Your capacitors should not be near the openings of the enclosure.

-

Remove the thermal tape's backing and press down on the the corners to install in the same fashion you aligned it.

-

Once you install anything with thermal tape, it is difficult to adjust. Measure/align twice to ensure you only have to do it once.

-

-

-

Locate the remote's receiver, which is a small black wire with a black rectangle sticker at the end of it.

-

The ESC Enclosure should have the cables coming out on the side closest to you. The side with cut-outs should be facing away from you.

-

Peel the sticker backing off and install it on the right side of the enclosure casing. Do not let it hang off the edge or have any sharp creases.

-

Once installed, cover the receiver cable with a small piece of electrical tape to secure it down.

-

-

-

Grab two of the rubber cable gaskets.

-

Cut a line down the middle of the recessed part, making a slit for the cables to come through.

-

Be careful not to cut the entire thing! Only a slit is needed, not hollowing it out.

-

Set these aside for now, you'll need them soon.

-

-

-

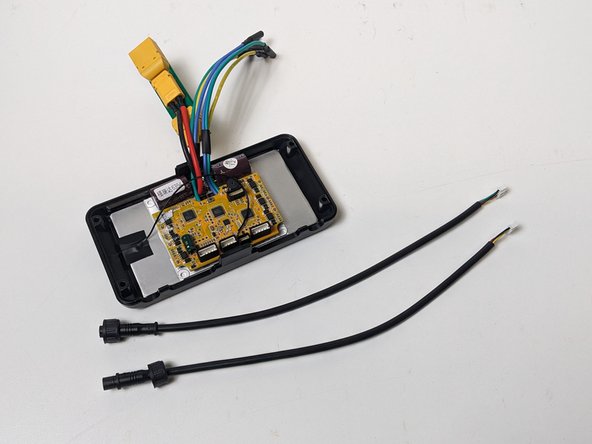

Grab your ESC and 2 motor sensor cables.

-

Plug your motor sensor cables into the outer ports on the port-side of your ESC.

-

-

-

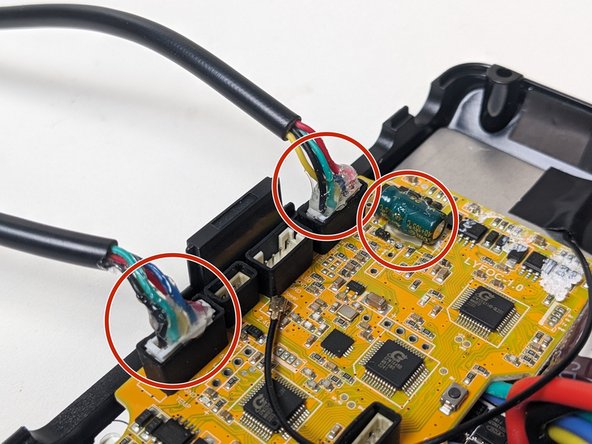

Now it's time to use Hot Glue. Grab your hot glue gun and heat it up.

-

Use caution and care when using or operating around a Hot Glue Gun, as it can easily burn you or leak Hot Glue onto other materials or yourself.

-

Hot Glue the sensor cable wires to it's port, this will ensure the cables do not have loose connections.

-

Add Hot Glue to the small green capacitor shown in the photo.

-

Hot Glue the receiver’s cable to the ESC/Main Capacitor to secure it down. You may need to hold it's position while the glue dries.

-

We add Hot Glue to these components to both hold them in place and protect them against potential damage or shifts caused by riding vibrations.

-

-

-

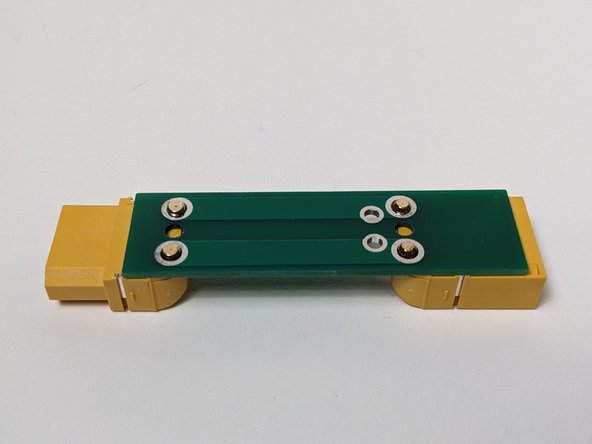

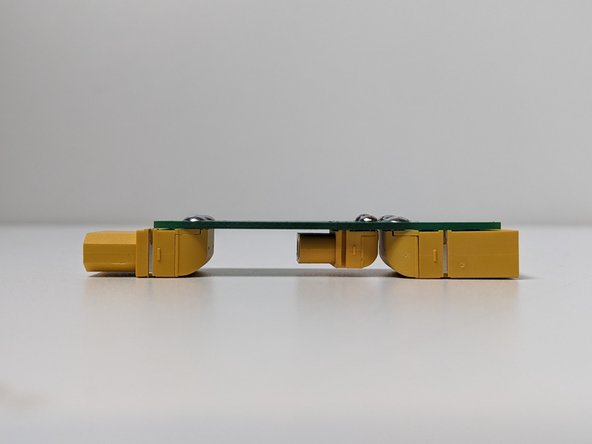

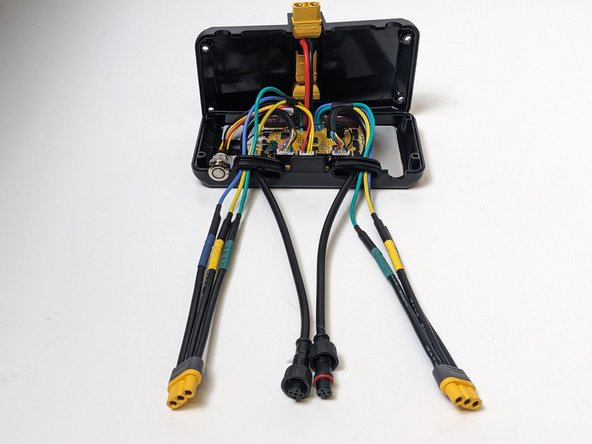

Gather your ESC Enclosure Base, and ESC, It's time to test fit your ESC's PCB into the enclosure's Rail.

-

The Xt90's being flush to the bottom of the enclosure is important, or else connecting batteries will become difficult.

-

Identify the appropriate tabs on the Enclosure Base with the holes on the PCB.

-

The Female XT90 plug should be away from the side with cable openings. (Refer to photos)

-

Push the XT90 onto the appropriate tabs to make the plugs flush to the bottom of the enclosure

-

-

-

Grab your switch, it's now time to plug-in and install it.

-

Plug the switch into the compatible port, between the two sensor cables.

-

Back the switches screw-back off to fit the thickness of the enclosure. (Shown in photo)

-

Add some hot glue to behind the screw to secure it in place.

-

-

-

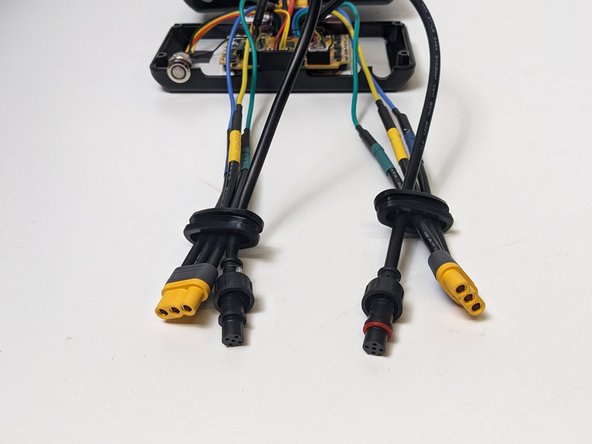

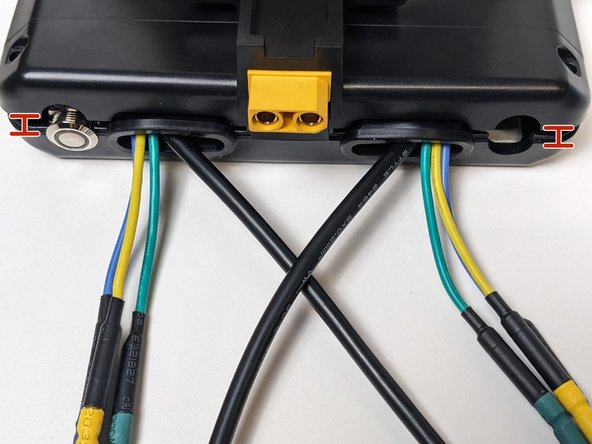

Gather 2 motor cable adaptors, and the Rubber Cable Gaskets that were cut in step 9.

-

Connect the cable adaptors to the matching color bullet connector, be careful not to cross sides.

-

Bullet connectors are the single pin connectors on the colored-cable end. The yellow connectors are MR60 plugs.

-

Now it's time to route the cables through the rubber gaskets.

-

First, route the sensor cables through and push to the center-most side. Then route the MR60 through.

-

Make sure the cables are not tangled, crossed, or taking up excess space. Space within the enclosure is minimal and cable management is important.

-

-

-

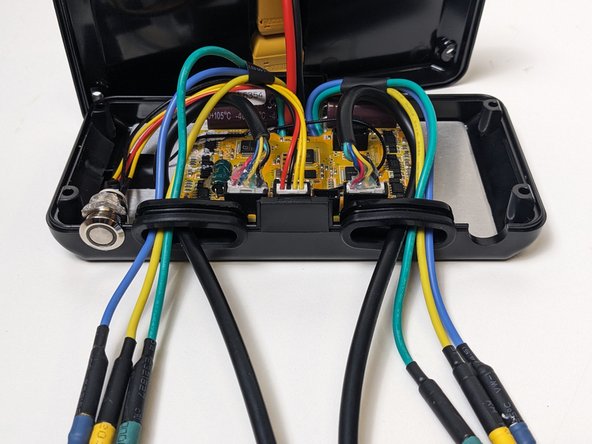

Slide the Rubber Cable Gaskets up the cables to the cable cutouts on the ESC enclosure.

-

Tuck and pull the cables through to make space in the enclosure.

-

The Goal here is to ensure that now cables will be crushed, crimped, or broken by the enclosure closing.

-

Be sure not to have cables in any of the 4 corners. Screws will be going through these holes with no room to spare.

-

-

-

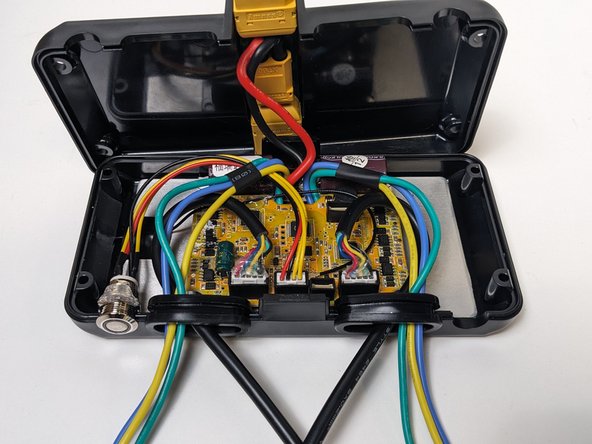

With your wire's properly tucked. and managed, it's time to connect both sides of the ESC's enclosure.

-

Lift the bottom case (side with PCB) by the corners and lower the case evenly on all corners.

-

Make sure the enclosure tab's are aligned and within the designated area. Keep an eye on maintaining the position of the rubber gaskets and switch.

-

Do not forcefully push down! There should be some resistance, but not enough to break anything or to cause difficulty.

-

-

-

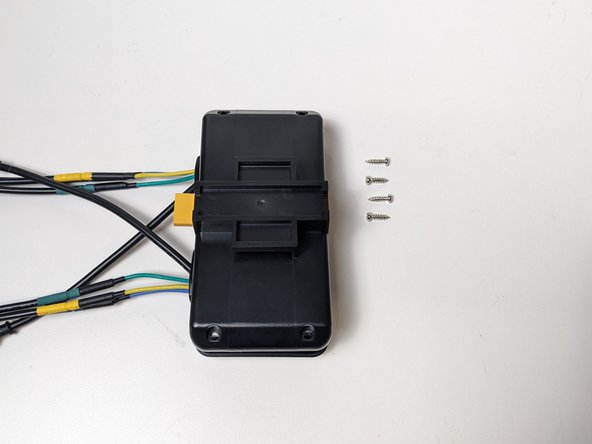

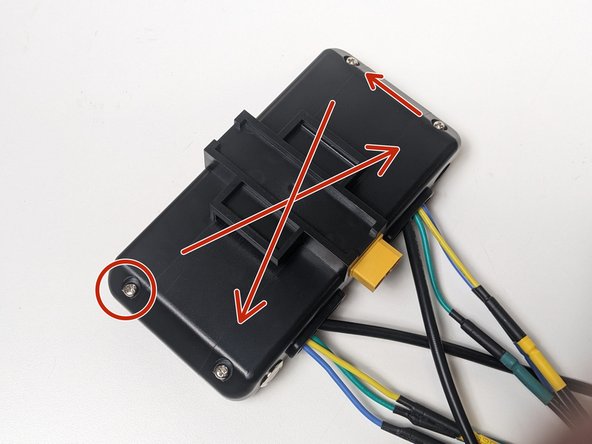

Gather 4 of your enclosure screws, it's time to connect both sides!

-

You're going to add the screws in a two step process.

-

First, screw each corner in half-way, working in a diagonal pattern.

-

Then repeat the same pattern to tighten the screws fully.

-

Do not over-tighten any screws! Over tightening could lead to broken screws and inoperable ESC enclosures.

-

-

-

Flip your ESC over and grab your rubber stopper.

-

Work your rubber stopper into the round port opposite of the ESC's switch.

-

You've just assembled your board's ESC! Now it's time to test by plugging into a battery and connecting a remote!

-

Be sure to wear helmets and protective gear whenever riding or operating your vehicle in any capacity.

-

Almost done!

Finish Line