Tools

Parts

- 31" Tayto Deck

- 97mm Skateboard Wheels

- Truck Hanger × 2

- Truck Baseplate wow × 2

- 1/4in Riser × 2

- Bearing Set

- Truck Hardware Set

- Wheel Pulley × 2

- Motor Pulley × 2

- 265m-12mm Belt × 2

- Motor Mount × 2

- Motor Hardware Set

- 6354 Motor × 2

- Tayto Enclosure

- Enclosure Hardware Set

- 10s3p Battery

- 10s3a Charger

- Dual ESC

- VX1 Remote

- Griptape Hexagons × 50

-

-

Gather the wheels, bearings, T Tool, and one truck hanger

-

Use the T tool to remove the locknut and washers from one side of the truck

-

Place one bearing onto the truck with the black covered side towards the center

-

-

-

Push a wheel onto the bearing and truck to install it

-

Place one bearing onto the truck with the black covered side towards the center. Then add a silver spacer onto the truck

-

Push the wheel onto the bearing and truck to install it

-

-

-

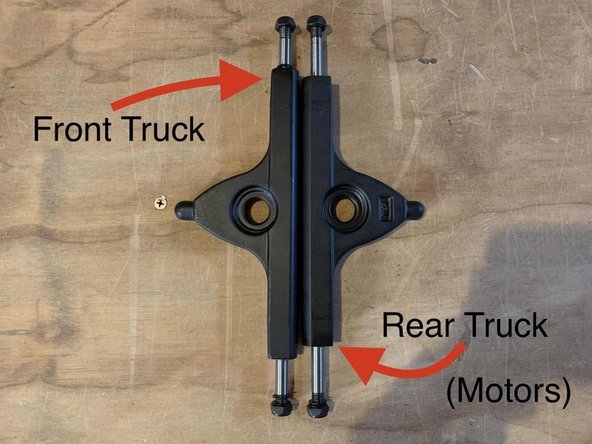

Later on in the tutorial you will need to know the difference between the front and rear truck

-

The front truck has a longer hanger

-

The rear truck has a shorter hanger to accommodate the wheel pulley

-

-

-

Gather the truck baseplates, truck hangers, and T-Tool

-

Remove the locknut from each baseplate

-

Remove one bushing and washer from each baseplate

-

Place a truck hanger in the baseplate with the words facing inward

-

-

-

Place the bushing and washer back on and tighten the locknut

-

If your having trouble getting the locknut to start threading, make sure the hanger is pushed all the way into the base of the baseplate (where the hanger comes to a rounded point). You can also apply pressure down on the truck to compress the bushings

-

Repeat this process to complete two trucks

-

-

-

Gather the front truck, two wheels, and T-Tool

-

Remove one locknut and one washer from each side of the truck. Make sure there is still one washer on the truck

-

Place one wheel on each side with the letters facing outward

-

Add the washer and locknut back onto the truck. From inside to outside the components should be arranged: washer, wheel, washer, locknut

-

Repeat on the other side to secure both wheels

-

-

-

It is very important not to over tighten the locknuts. It will create much more rolling resistance

-

Tighten the lock nuts until they touch the bearing. Then loosen the lock nuts ~ half a turn. You should be able to very lightly move the wheel laterally on the axle. If there is no movement it is too tight, and if the wheel can slide the lock nuts are too loose

-

-

-

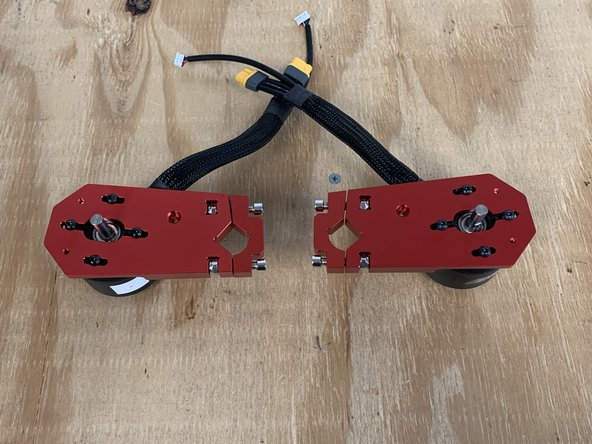

Gather the motors, motor mounts, cross bar, Loctite, and motor hardware

-

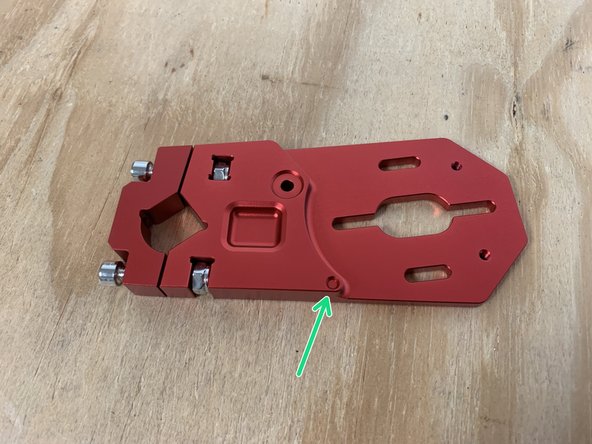

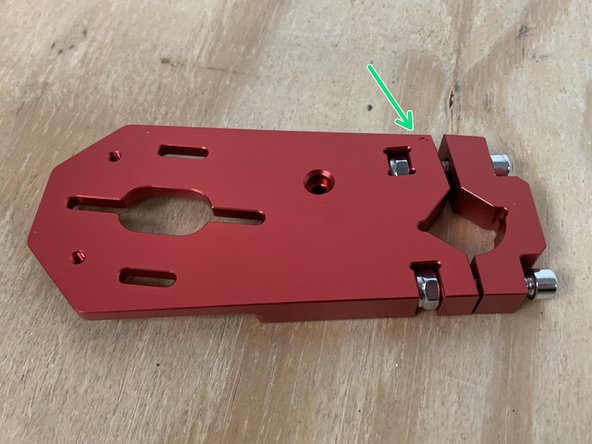

One motor mount has a dot cut out on each side. This needs to have the left motor (marked with an 'O' sticker) attached to it

-

One motor should have an 'O' sticker, but if it does not that is okay. You can use either motor and switch the motor direction later if need be

-

To open the loctite, break off the end cap and then flip it over to puncture a hole in the capsule (there is a prong on the inside of the cap).

-

We no longer include the Red Cross bar with the motor mounts. So, do not expect it to be in your package.

-

-

-

Place the motor mount on top of the motor with the wires oriented as shown

-

Add a drop of loctite to each motor screw before installing

-

Anytime there is a blue circle in a photo it represents where a drop of loctite needs to be added

-

Install 4 motor screws to attach the motor to the motor mount.

-

-

-

Repeat this process to attach the other motor to the motor mount

-

Ensure you use Loctite on each bolt

-

-

-

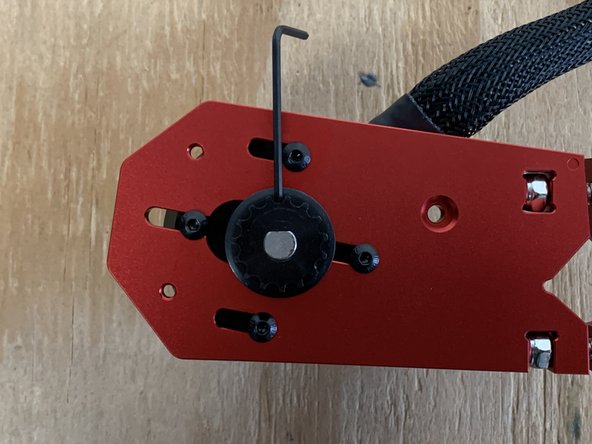

Gather the motor pulleys, 2mm Allen wrench, and Loctite

-

Remove the set screw from the motor pulley

-

Add Loctite to the set screw

-

Reinstall the set screw into the pulley. If you turn the set screw in too much to the point it is visible in the center of the shaft hole, it will not slide onto the motor

-

Repeat this process for the other motor pulley

-

-

-

Add two drops of Loctite to each motor shaft

-

Place the motor pulley onto the motor shaft

-

It is a tight fit and need to be aligned properly. If the motor pulley only goes part of the way on, use the Allen wrench to loosen the set screw

-

Ensure the motor pulley is pushed all the way on the motor shaft and then tighten the set screw

-

-

-

Repeat this process to install the motor pulley on the other motor

-

-

-

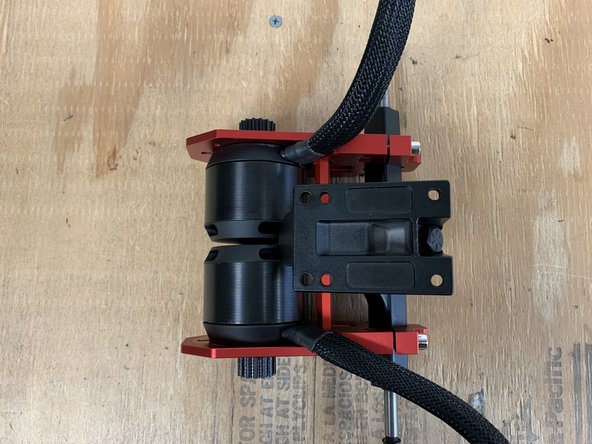

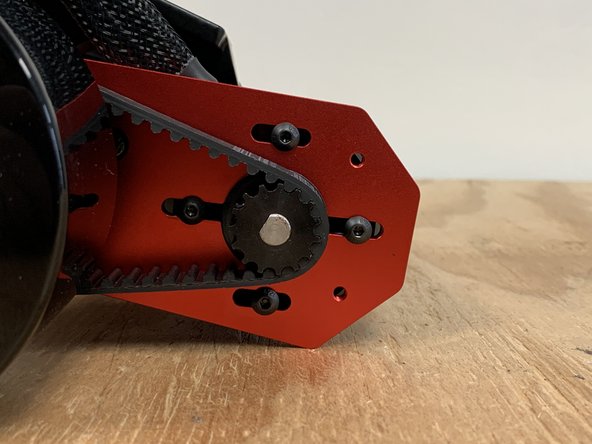

Use the 5mm Allen wrench to loose the motor mount bolts

-

Slide the motor mounts onto the rear truck

-

They should go on the side of the truck with the "protrusion"

-

Remove the two bolts from the cross bar

-

-

-

Since the cross bard is no longer included you will need to install the motor mounts in a different manner. You can align the motor mounts by eye (to the center) and then use the black 3d printed spacer to place between the wheel pulley and motor mount for final alignment.

-

Align the motor mount assembly to the center of the truck. There should be even spacing on both sides of the truck

-

Tighten the bolts on the motor mount evenly. You should turn each bolt 1/4 to 1/2 a turn at a time. Then tighten the other bolt 1/4 to 1/2. This ensures there is even pressure on each bolt

-

There is a gap on the top and bottom in between the clamp and motor mount. This gap should be the same on the top and bottom. If they are different, loosen the bolts and retighten them

-

-

-

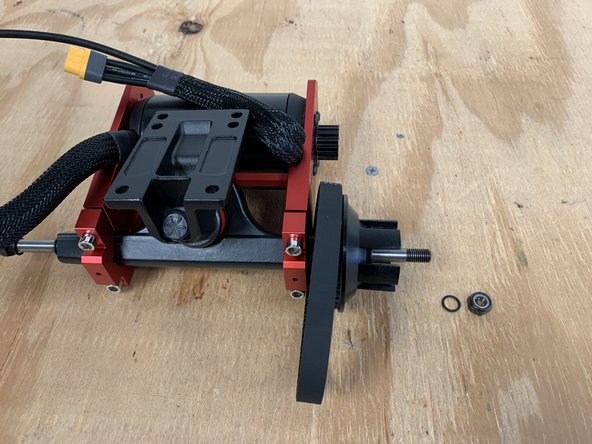

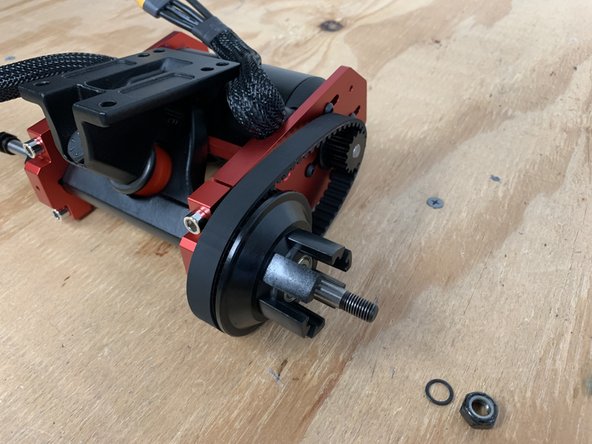

Use the T Tool to remove the locknut and 1x washer from the truck

-

Slide the wheel pulley and belt onto the truck

-

Place the belt over the motor pulley. You will need to slide the motor all the way forward and the four bolts securing the motor will need to be loose to accomplish this

-

-

-

Slide the wheel onto the truck with the words facing outwards

-

Add the washer and locknut back onto the truck. Tighten with the T Tool

-

Do NOT over tighten the locknut. You should be able to move the wheel laterally on the axle back and forth ever so slightly

-

-

-

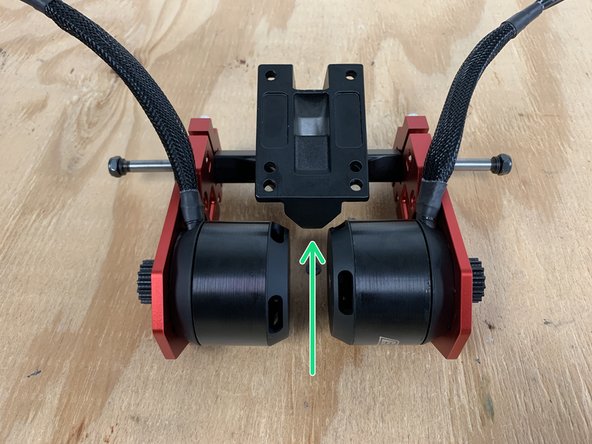

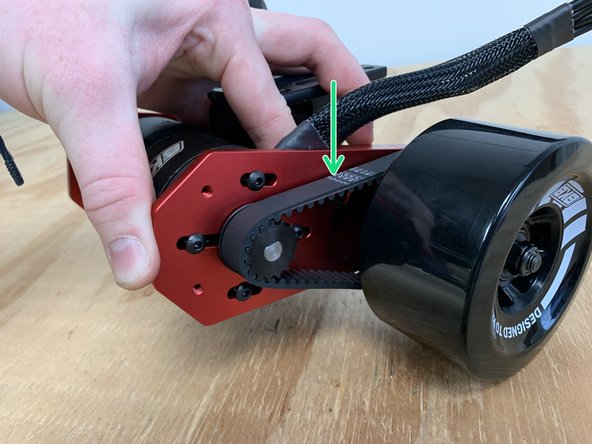

Now it is time to tension the belt. Pull back on the motor until the there is decent tension in the belt

-

While holding tension in the belt tighten one bolt

-

You can now test the tension by pressing down in the area located at the green area. The belt should move up and down 2-3mm with your press.

-

If it is too stiff and does not move, there is too much tension in the belt. Loosen the bolt and try again

-

If the belt depresses more than 4mm, there is not enough tension. Loosen the bolt and apply more tension.

-

When the proper tension has been achieved, tighten all four bolts to lock the motor in position

-

-

-

Repeat steps 18-20 to complete assembly of the other side of the drivetrain. Ensure proper belt tension

-

-

-

Gather the front truck, rear truck, deck, truck hardware, risers, T Tool, and 3mm Allen wrench

-

Place four of the truck bolts through the holes at the front of the deck

-

Add a riser to the bolts

-

Place the front truck on the bolts orientated as shown

-

-

-

Flip the board over and place 4x truck bolts through the holes at the rear of the deck

-

Add a riser to the bolts

-

Place the drivetrain onto the bolts with the motor mounts facing the rear

-

Add the two wire clips to the motor wires and place them over the two inner truck bolts

-

-

-

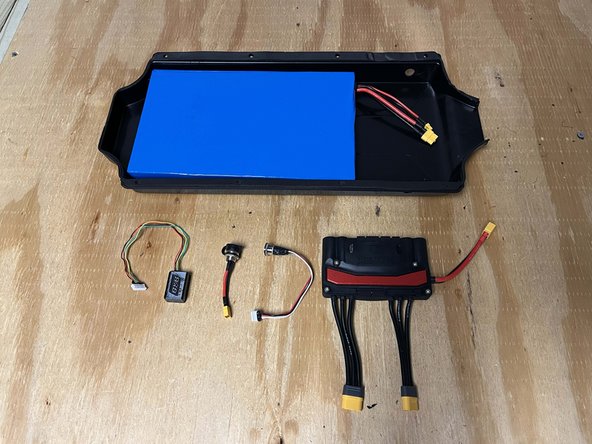

Gather the enclosure, battery, charge port, Xenith, switch and Voyager Receiver

-

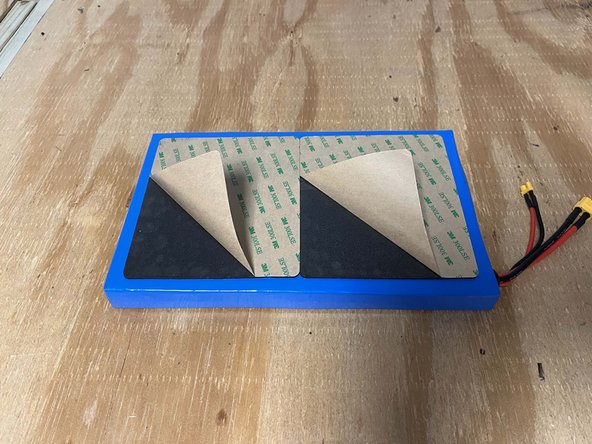

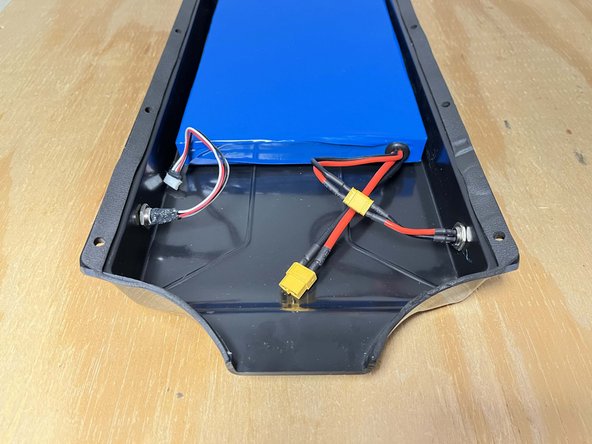

Peel the paper backing off of the batteries adhesive pads

-

Firmly press the battery into the enclosure as shown to secure it in place

-

-

-

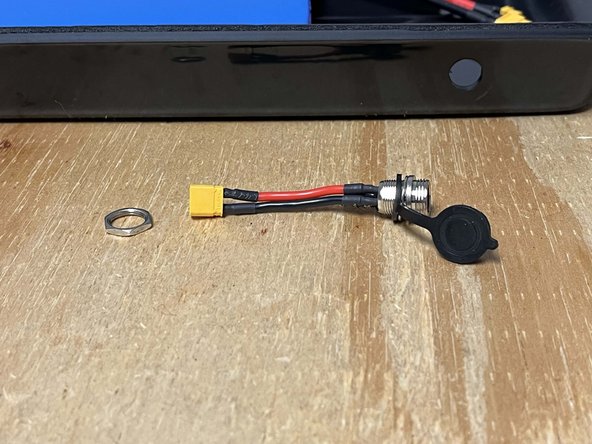

Remove the locknut from the charge port

-

Place the charge port through the hole in the enclosure as shown and secure it with the locknut

-

-

-

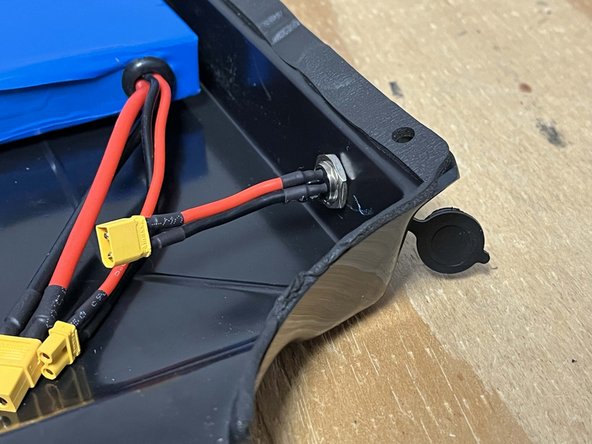

Remove the locknut from the switch

-

Place it through the hole in the enclosure and secure it with the locknut

-

-

-

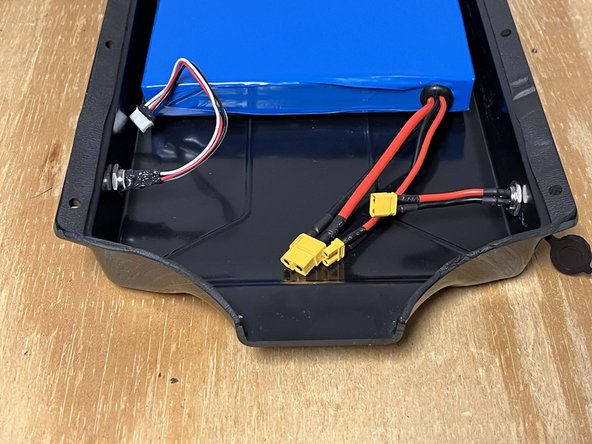

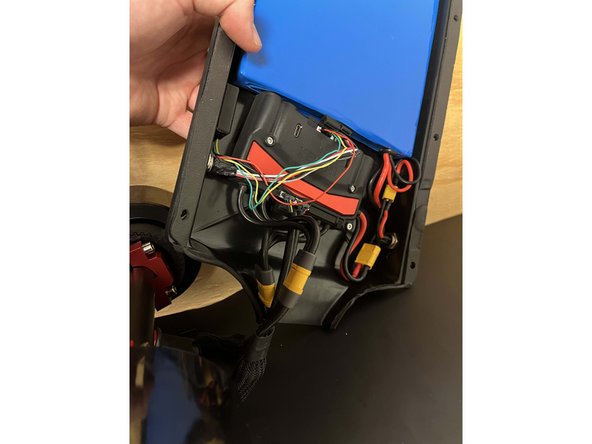

Plug the charge port into the battery

-

Place the Xenith in the enclosure as shown

-

Plug the Xenith into the battery

-

Situate the cables and neatly arrange them

-

-

-

Plug the switch into the Xenith's SWITCH port

-

Peel the paper backing off of the Voyager receiver and place it in the enclosure as shown

-

Plug the Voyager receiver into the Xenith's UART port

-

-

-

With the board on its side place the enclosure near the drivetrain to plug in the motors

-

Plug the lower motor into the right side of the Xenith. Connect the large Yellow connectors and then plugin the white connector into the SENSOR 2 port

-

It is VERY important NOT to get the yellow and white connectors crossed. You need to make sure the yellow and white connector from each motor is plugged into the same side of the Xenith

-

Plug the lower motor into the left side of the Xenith. Connect the large Yellow connectors and then plugin the white connector into the SENSOR 1 port

-

-

-

Carefully arrange the enclosure on the deck so it aligns with the holes in the deck

-

Place an enclosure bolt through the deck and into each hole in the enclosure

-

The order of components should be as follows: bolt, deck, enclosure, rubber washer, metal washer, locknut

-

DO NOT OVERTIGHTEN the bolts, or you will crack the enclosure.

-

The gasket should just barely compress, and there should be small gap between the washer and lock nut due to the angle of the enclosure.

-

-

-

Turn the remote on by long pressing the power button (left)

-

Enter the settings menu by long pressing the settings button (right)

-

Click enter (right button) to enter the board parameters menu

-

Press enter to enter the battery cells setting

-

Move the throttle up and down to change the value. If you have the small battery (10s3p) ensure the value is 10S. If you have the larger battery (TypeR) ensure the value is set to 12S. When the value is set press the exit button (left).

-

Use the throttle to navigate the other settings within the board parameter menu. Change the values to match your current setup

-

Pole Pairs = 7. Wheel Type = Pulleyed. Wheel Diamater = 97mm, 105mm, or 150mm depending on your wheel choice. Motor pulley = 15C for standard and 20C for the speed upgrade. Wheel pulley = 40C for 97 or 105mm wheels, 60C for 6in wheels. Unit = your choice. Xenith FW = DISABLE. Then click exit to return to the menu.

-

Navigate to the Remote Config menu and press enter. Go to the gear calibration and press enter. Apply full throttle, then full brake, then full throttle, and then full brake. Press and hold the save button. Then click exit to return to the menu

-

-

-

We will now pair the remote to the receiver. Ensure that the skateboard is turned off. Navigate to the Receiver Config menu, press enter.

-

Click enter on BINDING. The words will then begin to blink. Then turn the board on and the remote will pair. Click exit twice to return to the main screen.

-

You can learn more about how to use the remote here: Using the Voyager Remote

-

It is highly recommended to ride the board for the first time in the low acceleration mode.

-

-

-

ALWAYS WEAR A HELMET! THEY SAVE LIVES. DONT WEAR IT FOR YOU, WEAR IT FOR YOUR FAMILY.

-

Electric skateboarding is a very fun and rewarding sport. But, everyone has fallen off their board at some point. It's not a matter of if it will happen, but when it will happen. Please wear at least a helmet and always ride within your comfort zone

-

Treat the board with respect! It is a vehicle after all. Do NOT drop the board from a vertical position to set it down as it put a lot of stress on the enclosure. Give the board a good once over before every ride to make sure bolts are tight and things look normal.

-

NEVER CHANGE THE FIRMWARE ON THE XENITH! IF YOU ARE HAVING AN ISSUE REACH OUT TO SUPPORT BEFORE CHANGING ANY SETTINGS ON THE XENITH!

-

Please consider leaving a review on our website and helping us spread the word on Facebook/Reddit/Instagram/etc. We do NOT do any paid marketing, we believe the product and our customers speak for themselves. Every little bit helps!

-

Cancel: I did not complete this guide.

One other person completed this guide.